Phone: 0086-159-3381-6712

Phone: 0086-155-0324-9408

Tel/Fax: 0086-318-5227-301

E-mail: sales@wiremesh-chinafree.com

WhatsApp : 159-3381-6712

Address: Nanhuan Road, Anping County, Hengshui, Hebei, China. Post Code: 053600

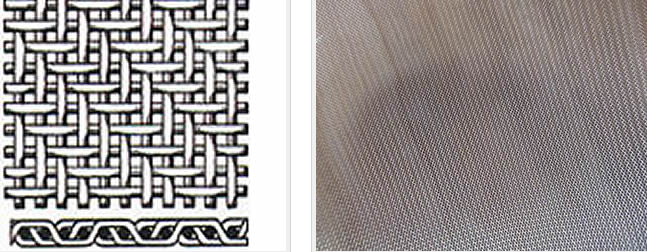

Stainless steel twill weave wire mesh is widely used in petroleum and chemical industry because of its stable material, flat surface and no dirt, uniform mesh hole without deformation, good elongation and abrasion resistance. Stainless steel twill weave wire mesh is mainly made of stainless steel wire 316L, 316, 304L, 304.

Material: stainless steel wire 316L, 316, 304L, 304, 302, 201

Type 304 generally refers to "18-8" (18% chromium, 8% nickel) which is mostly a basic stainless steel alloy and is very suitable for mesh fabrics. It can be exposed to the outside world and will not rust or oxidize when the outside temperature rises to 1400 degrees Fahrenheit.

Type 304L is very similar to T-304 in that it reduces carbon content and facilitates braiding and re-welding.

Type 316 can be stabilized by adding 2% molybdenum, and T-316 is an "18-8" alloy.

It is less susceptible to corrosion in brine, sulphur water or halogen than other Chromium-Nickel Stainless steels, such as chlorides, for example. The most valuable feature of T-316 is its increased creep resistance as the temperature rises. Other mechanical and structural characteristics are the same as those of T-304.

Type 316L is very similar to T-316 in that it reduces carbon content and facilitates braiding and re-welding.

| Stainless steel twill weave wire mesh specifications | |||

| mesh | wire diameter | opening size | standard roll size |

| 250x250 | 0.040 | 0.063 | 1x30m, 1.22x30m |

| 300x300 | 0.040 | 0.044 | 1x30m, 1.22x30m |

| 325x325 | 0.035 | 0.043 | 1x30m, 1.22x30m |

| 350x350 | 0.030 | 0.042 | 1x30m, 1.22x30m |

| 400x400 | 0.030 | 0.033 | 1x30m, 1.22x30m |

| 450x450 | 0.028 | 0.028 | 1x30m, 1.22x30m |

| 500x500 | 0.025 | 0.026 | 1x30m, 1.22x30m |