Phone: 0086-159-3381-6712

Phone: 0086-155-0324-9408

Tel/Fax: 0086-318-5227-301

E-mail: sales@wiremesh-chinafree.com

WhatsApp : 159-3381-6712

Address: Nanhuan Road, Anping County, Hengshui, Hebei, China. Post Code: 053600

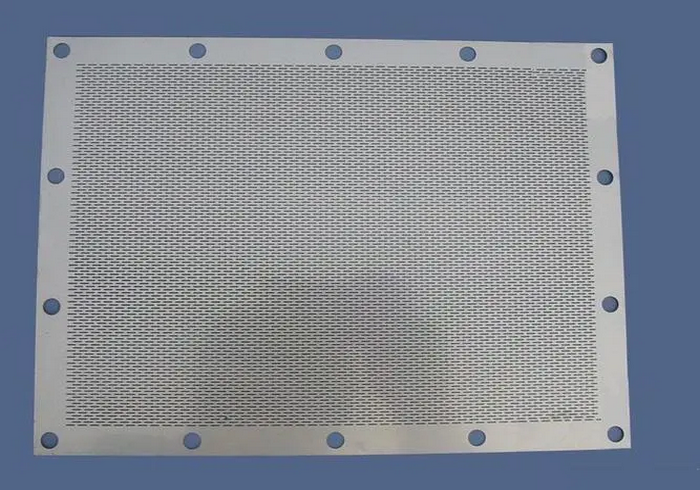

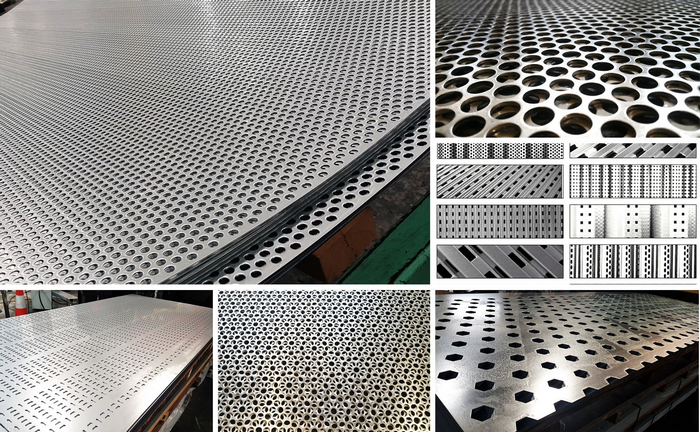

Chemical Etching Metal Mesh Chemical etching is a process that is used to make intricate patterns and shapes on metal surfaces. The process involves using an acid or a chemical solution to selectively remove parts of the metal surface, leaving behind the desired pattern. Metal mesh is a type of metal surface that is commonly used in various applications, such as in filters, screens, and separators.

Etching metal mesh is widely used in electronics, encoders, motors, models, computers, optics, hardware, machinery, communications, automotive, etc.

The chemical etching process involves several steps. The first step is to prepare the metal surface by cleaning it thoroughly. This is done to remove any dirt, grease, or other contaminants that might interfere with the etching process. Once the surface is clean, a mask is applied to the parts of the surface that are not to be etched. The mask can be made from a variety of materials, such as tape, wax, or photoresist. The mask is then exposed to a pattern that is to be etched onto the metal surface. The next step is to immerse the metal surface in a chemical solution that will selectively etch the exposed parts of the surface. The solution can be an acid, such as hydrochloric acid or nitric acid, or a chemical that can dissolve the metal surface, such as ferric chloride.

The etching process takes place at a controlled temperature and for a specific amount of time. The etching time depends on the thickness and type of metal being etched, as well as the desired depth and resolution of the pattern. Once the etching is complete, the metal surface is rinsed with water to remove any remaining chemical solution. The mask is then removed, revealing the etched pattern. The final step is to clean the metal surface again to remove any residual chemicals or contaminants. The resulting metal mesh is a precise and intricate pattern that can be used in various applications. Chemical etching metal mesh has several advantages over other methods of creating patterns on metal surfaces. It is a cost-effective process that can be used to create complex patterns with high precision and resolution. It also allows for the creation of patterns on thin and delicate materials that cannot be easily machined or stamped.

Additionally, chemical etching can be used to create patterns on both sides of the metal surface, which is not possible with other methods.

In conclusion, chemical etching metal mesh is a versatile and precise process that can be used to create intricate patterns on metal surfaces. It is a cost-effective method that offers high precision and resolution, and it is suitable for use on thin and delicate materials. With its many advantages, chemical etching metal mesh is an ideal solution for a wide range of applications.