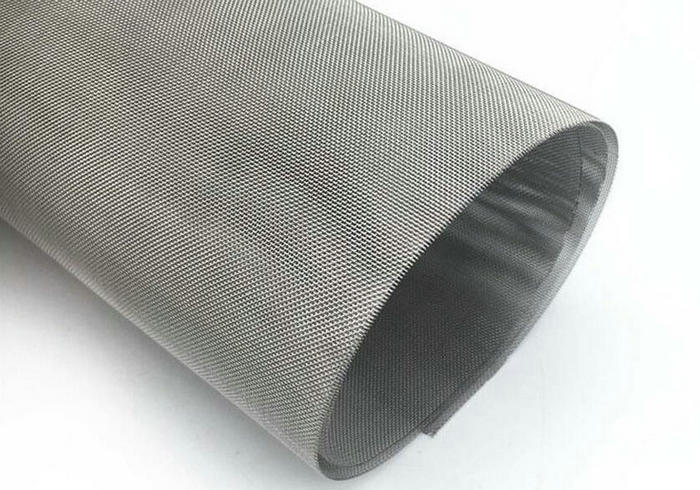

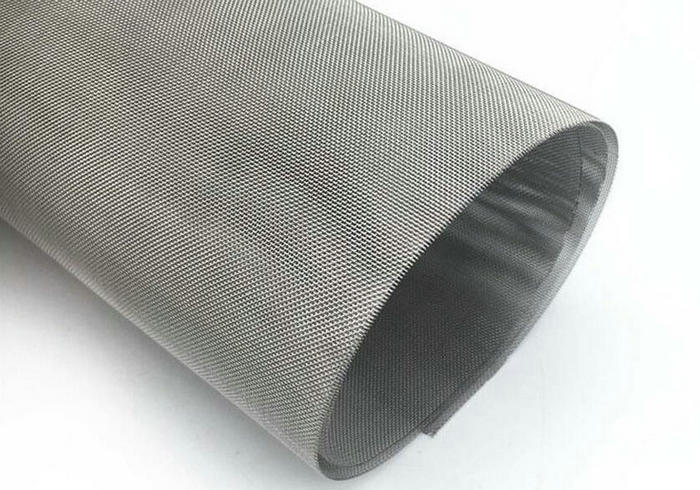

Inconel Alloy Wire Mesh Standards, Characteristics, Uses

Inconel wire mesh is a type of woven wire mesh made of inconel wires. The inconel is the alloy of nickel, chrome and iron. According to the chemical composition, the inconel can be divided into inconel 600, inconel 601, inconel 625, inconel 718 and inconel X750.

Without magnetism, inconel wire mesh can be used in a temperature range from below zero to 1093 degree. Inconel wire mesh has excellent corrosion resistance, and its oxidation resistance performance is better than the nickel wire mesh. It is widely used in the petrochemical, aerospace industry and other fields.

Features of Inconel Wire Mesh:

Inconel Wire Mesh features corrosion reistance; acid and alkali resistance; high temperature resistance; salty resistance; chemical stability; outstanding filtering performance

Applications of Inconel Wire Mesh:

The application fields include: retort furnaces, muffle furnaces, heat treatment fixtures and baskets, vacuum furnace devices, chlorination equipment with a maximum working temperature of 1000 degrees Fahrenheit, titanium dioxide factories, retort furnaces, heaters, distillers, bubble cap towers, and condensers in fatty acid processes, evaporator tubes, tube plates, and platens in sodium sulfide manufacturing, and rosin acid treatment equipment in pulp manufacturing.