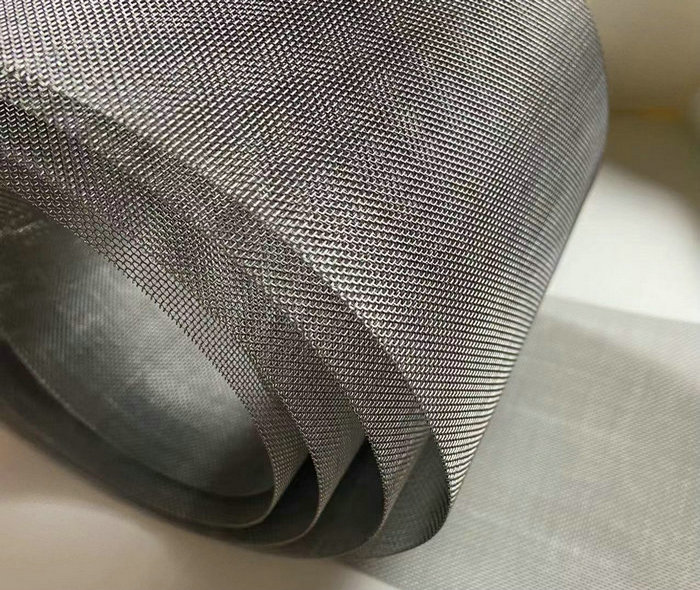

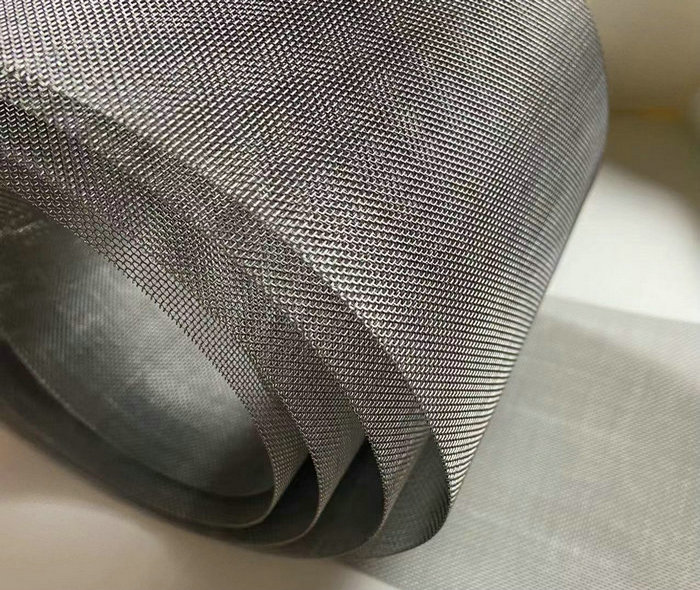

120 mesh pure nickel wire mesh for hydrogen production

Nickel mesh has a series of excellent characteristics, so it is widely used in high-tech fields and industrial sectors such as metallurgy, chemical industry, petrochemical industry, electronic technology, shipbuilding, and aviation industry.

Nickel mesh: According to the production process, the nickel mesh is divided into: nickel wire woven mesh, nickel plate stretched mesh, nickel plate punched mesh.

1. Nickel wire woven mesh: It is made of nickel wire cross-woven according to warp and weft. The mesh is square hole and rectangular hole. The mesh number of nickel wire weaving is 0.5 mesh---300 mesh. Net width: 20mm—1200mm.

2. Nickel plate stretched mesh: It is made of nickel plate by mechanical stamping and stretching, and the mesh is diamond-shaped.

Mesh thickness: 0.05 mm--8 mm. Mesh width: 5 mm--1000 mm.

Mesh: 0.3X0.6mm, 0.5X mm 1, 0.6X1.2 mm, 0.8X1.6 mm, 1X2 mm, 1.25X2.5 mm, 1.5X2 mm, 1.5X3 mm, 2X2.5 mm, 2X3 mm, 2X4mm, 3X6mm, 4X8mm, 5X10mm, 6X12mm, etc.

3. Nickel plate punching mesh: It is made of nickel plate by mechanical punching. Hole shape: round hole, semicircular hole, square hole, square hole, straight hole, triangular hole, hexagonal hole, etc. Mesh thickness: 0.04mm-8mm. Net width: 10mm--1000mm. Mesh: 0.8mm-25mm.

3. Deep processing of nickel mesh:

Nickel mesh punching, nickel mesh slitting, nickel mesh punching, nickel mesh reserved ears and other deep processing.

4. Specifications of nickel wire woven mesh: 10 mesh, 20 mesh, 30 mesh, 40 mesh, 60 mesh, 80 mesh, 100 mesh, 120 mesh, 150 mesh, 180 mesh, 200 mesh, 250 mesh, 300 mesh, 363 mesh, 400 mesh

(Physical factory, producing wire mesh, special alloy wire mesh, heat-resistant high temperature mesh, rich experience, welcome to consult)